Despite the fact that 3D printing is frequently considered a new innovation in disruptive technology, the idea was actually first introduced in science fiction in the 1940s. Later on, it resurfaced in the 1970s when creator Johannes F. An inkjet metal-material device that operated on a reusable surface by melting and remelting a removable metal fabrication was the Liquid Metal Recorder, which Gottwald invented and patented.

That is not to say that the 3D printing technology of today is not innovative, but it does imply that the technology has a much longer history than most of us are likely to be aware of. 3D printers are widely used today to create everything from actual homes and other structures to human organs.

The 3Rs of sustainability—reduce, reuse, and recycle—are met by 3D printing, or additive manufacturing, which has been heralded as a key technology to boost the environmental credentials and sustainability of manufacturing. 3D printers don’t just make cool products—they can also make a positive impact on the planet by reducing waste.

Here is all the information you need to know about how waste is reduced by 3D printing products.

Table of Contents

What Is 3D Printing?

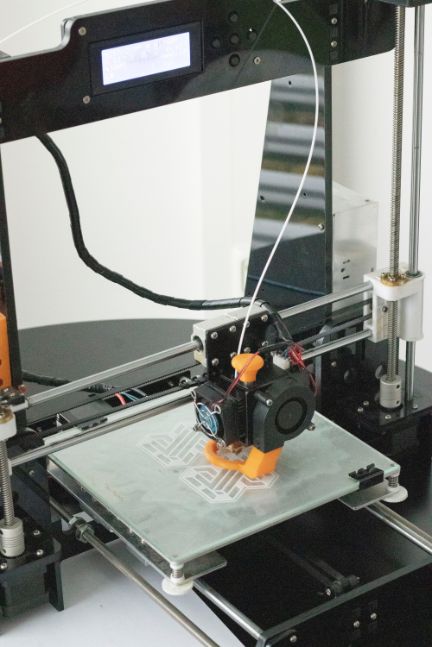

Although 3D printing was initially mainly used to produce low-quality prototypes and proof-of-concept products that were to be built using conventional building methods and materials, the concept has quickly advanced over the past ten or so years to cover a vast array of uses and designs.

3D printing—otherwise known as additive manufacturing—is the practice of making a three-dimensional object from a virtually created design or digital file. The process of creating an object using a 3D printer involves printing successive rows of material, each of which serves as a thin cross-section of the final object.

The development of 3D printing has led to a wide range of applications and techniques, from custom products and amateur and professional artwork to more sophisticated applications in the medical industry. Rapid prototyping and mass production are made possible by the majority of 3D printer’s ability to produce finished goods quickly from beginning to end.

How Much Does A 3D Printer Cost?

Over the past decade or so, entry-level 3D printers have become more and more affordable, with printers available for hobbyists and parents looking for STEM- or creativity-inspired printers for kids. For 3D printers and accompanying pens made for kids, prices range from $100 to $300, while entry-level printers made for hobbyists and at-home use cost between $300 and $500.

While the quality and capabilities of professional-grade 3D printers can vary greatly from printer to printer, you should expect to pay anywhere from $1,500 to well over $20,000 for a 3D printer that can produce more intricate projects, like sculptures and novelty or bespoke items.

Greater financial investment is needed by businesses that use 3D printers to produce more complex products like 3D-printed homes, automotive and aviation parts, and even human organs. Industrial 3D printers are not only difficult to obtain but also cost a business well into the six figures.

How Do 3D Printing Products Reduce Waste?

Materials are frequently not used effectively in traditional manufacturing. The process is typically subtractive, which means that you start with a sizable block of material, chip away at it to create a product, and then discard the waste. 3D printing, on the other hand, is an “additive” process, building a product layer by layer.

The printer adheres to a computer-aided design (CAD), leaving voids in the center or other places where the material isn’t required. It eliminates the need to carve or trim extra material because it only uses the exact amount required in an exact way. Therefore, there are significantly fewer scraps.

Experts claim that 3D printing in the construction sector can reduce waste by 95% or more. “Depending on the technology, it has the potential to unlock truly zero-waste construction, eliminating approximately 4.4 pounds per square foot, on average, that go to landfills [when building] a traditionally constructed home,” says Sam Ruben a co-founder and senior sustainability adviser at the 3D-printed buildings company Mighty Buildings in California.

Fewer leftovers going to the landfill means fewer greenhouse gas emissions, toxins leaching into the ground, and pollution, all of which can slow climate change.

And there are countless uses for it in the manufacturing industry, whether you’re making furniture, cars, space shuttles, homes, or other things. 3D printing also reduces waste before you even start creating a product because you can create more effective prototypes.

It is simpler to determine which components need to be improved and which might fail because a significant portion of the design process is performed on a computer, with AI assisting in the creation of amazing simulations. Because of this, you don’t have to go through as many materials (which will eventually be thrown out) before you figure out how to make the thing you want.

The Future Of 3D Printing In Manufacturing

Future manufacturing will probably combine conventional techniques with 3D printing. The latter is typically more resource-efficient and enables inventive, efficient designs that help reduce the amount of manufacturing necessary. There is still room for improvement, despite the fact that it is cleaner, greener, and more sustainable than conventional manufacturing methods.